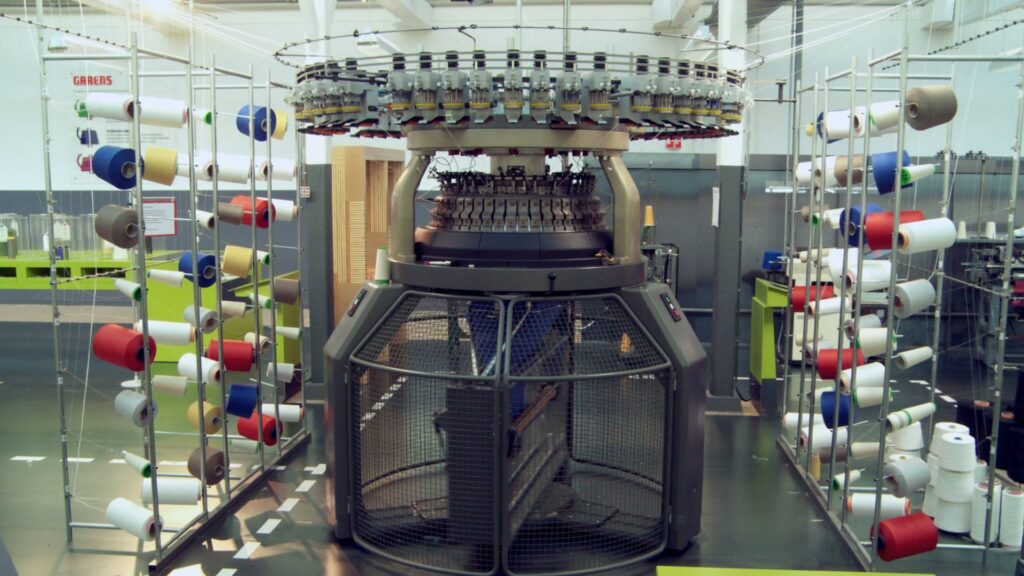

KNITTING

The process in which fabrics are produced by a set of connected loops from a series of yarn in a weft or warp direction is termed as knitting. The knitting process has been classified into two like warp knitting and weft knitting.. Our Knitting division equipped with Hi-tech machineries from Germany, Taiwan and Italy.

DYEING

Our Dyeing facility uses the latest Low Liquor Air Flow machinery manufactured by THEN, Germany with an automated chemical dosing system that discharges very low effluent and demands minimal human interference during the process. We have an installed capacity of 10,000 kgs of fabric per day. The water treatment plant situated at our facility is complete with chemical, biological, oxidization a four stage reverse osmosis and evaporator features, enables us to function as a Zero Discharge and a C2C Gold Facility™.

PRINTING

Our printing division is equipped with automated M&R printing machines from the United States. Particularly the Alpha 8 which is M&Rʼs exciting new take on the oval shaped press. It has the capacity to produce 18 different colours simultaneously.

EMBROIDERY

Our automated embroidery machines are made in Tajima, Japan equipped with different aspects of Embroidery such as cording, roping, sequins, boring and mirror work that significantly enhances and embellishes the garments. In addition, Applique Laser Cutting Machine and SEIT Laser Bridge enables multitasking of applique and embroidery. Machineries for Studs, stones and bead work are all in house.

CUTTING

We have an efficient cutting section with an in-house CAD system (GERBER) to ensure best fabric efficiency by reducing wastage.We can cut about 10,000 pcs per day.

PRODUCTION

Each and every garment is checked and finally pressed by vacuum ironing machine and are packed size wise, colour wise and country wise to reach the destination on time safely.We can pack 10,000 pcs per day.